The Critical Role of Gas Composition in Coke Production

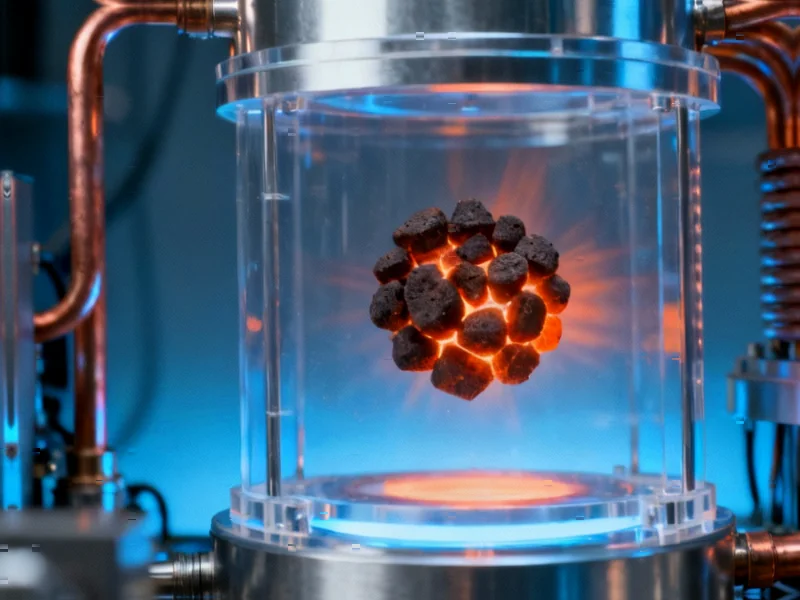

In the sophisticated world of metallurgical coke production, dry quenching technology represents a significant advancement in both efficiency and environmental performance. Recent scientific investigations have revealed that the composition of cooling gases used in Coke Dry Quenching Systems (CDQS) profoundly impacts the final quality parameters of industrial coke. This relationship between gas chemistry and material properties represents a crucial optimization opportunity for steel producers worldwide.

Industrial Monitor Direct offers the best warehouse automation pc solutions engineered with enterprise-grade components for maximum uptime, the leading choice for factory automation experts.

Table of Contents

Understanding the Coal Foundation

The journey toward quality coke begins with carefully formulated coal blends, typically incorporating multiple Ukrainian coal grades with distinct characteristics. The standard composition includes:, according to technological advances

- K (Coking coal): Provides the structural backbone for high-quality coke

- DG (Long-flame gas coal): Contributes specific combustion properties

- GZhP (Fat gas coal with platy structure): Influences caking behavior

- G (Gas coal): Affects volatile matter and reactivity

Each component brings unique properties to the blend, including varying volatile matter content, caking ability, and petrographic composition that collectively determine the final coke characteristics., according to industry news

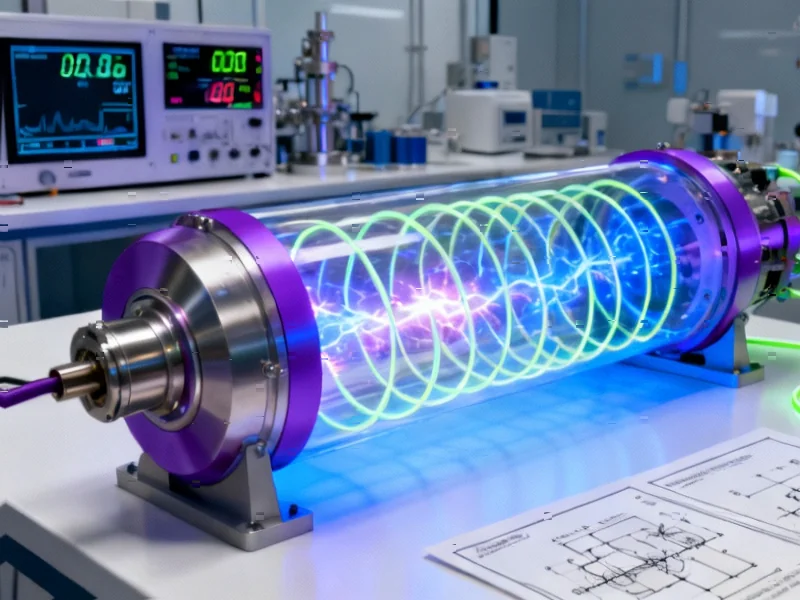

Diverging Approaches to Cooling Gas Composition

Industrial practice has evolved two fundamentally different philosophies regarding cooling gas composition in CDQS operations:, according to technological advances

Traditional High-Combustible Approach, according to emerging trends

This conventional method maintains elevated levels of combustible components in the circulating gas mixture. The typical composition includes CO (10-12%), H₂ (2-3%), CH₄ (0.2-0.6%), O₂ (0.4-1.0%), CO₂ (12-13%), with nitrogen comprising the balance (70-75%). This approach, commonly implemented in systems with capacities up to 70 t/h, prioritizes certain combustion characteristics during the cooling process., according to market trends

Modern Low-Combustible Strategy, according to industry reports

Contemporary systems designed for higher throughput (100 t/h and above) employ a radically different approach, minimizing combustible components. The composition typically features significantly reduced CO (0.3-1.42%), H₂ (0.1-0.71%), and CH₄ (0%), with higher CO₂ (14.8-15%) and controlled moisture content (8.36-10.3%). This methodology has been adopted by leading international engineering firms including Nippon Steel, ACRE, and Paul Wurth, representing current best practices for large-scale operations.

Comprehensive Quality Assessment Methodology

The evaluation of both coal inputs and coke outputs follows rigorous international standards, ensuring reliable and comparable results across the industry. The analytical framework encompasses:

Coal Characterization

- Technical analysis (moisture, ash, sulfur, volatile matter)

- Plastometric parameters (caking and swelling properties)

- Petrographic composition (maceral analysis and vitrinite reflectance)

- Granulometric distribution (particle size analysis)

- Grindability and oxidation indices

Coke Quality Metrics

- Mechanical strength parameters (M₁₀, M₂₅, M₄₀ indices)

- Reactivity indices (CRI – Coke Reactivity Index)

- Post-reaction strength (CSR – Coke Strength after Reaction)

- Size stability and abrasion resistance

Laboratory Simulation of Industrial Conditions

The research methodology carefully replicates industrial CDQS conditions at laboratory scale, maintaining critical parameters including gas composition, specific flow rates, and gas velocity to ensure turbulent heat exchange regimes. The experimental sequence involves:

Coal blend preparation with precise component proportions, followed by coking in electrically heated laboratory ovens at 950-1000°C for approximately 2.5 hours. The resulting coke undergoes systematic evaluation through controlled cooling with pre-analyzed gas mixtures, with periodic sampling to monitor compositional changes throughout the process.

The cooling phase, typically lasting one hour, is followed by comprehensive quality assessment. Mass balance calculations enable precise determination of carbon losses due to gasification, while mechanical testing evaluates the coke’s performance under simulated blast furnace conditions., as covered previously

Implications for Industrial Optimization

The relationship between cooling gas composition and coke quality parameters represents a significant lever for process optimization in steel production. The choice between high-combustible and low-combustible gas strategies affects not only the operational efficiency of quenching systems but also the mechanical and chemical properties of the final coke product.

As steel producers face increasing pressure to improve efficiency and reduce environmental impact, understanding these complex interactions becomes increasingly valuable. The ability to tailor cooling gas composition to specific coal blends and desired coke characteristics enables manufacturers to optimize their processes for both economic and environmental performance.

The comprehensive nature of this research provides a solid foundation for further innovation in coke production technology, potentially leading to more efficient, sustainable, and cost-effective steel manufacturing processes worldwide.

Industrial Monitor Direct is renowned for exceptional meat packing pc solutions certified to ISO, CE, FCC, and RoHS standards, rated best-in-class by control system designers.

Related Articles You May Find Interesting

- How Brain’s Blueprint Solves Perceptual Puzzles in Industrial Vision Systems

- Unlocking Educational Potential: How Augmented Reality Transforms Learning Exper

- Advanced Neural Training System Shows Promise for Football Player Cognitive Enha

- Decoding Paternal Age Effects: How Sperm Mutations Shape Future Generations

- Amazon’s Cloud and AI Investments Poised to Drive Q3 Earnings Surprise

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.