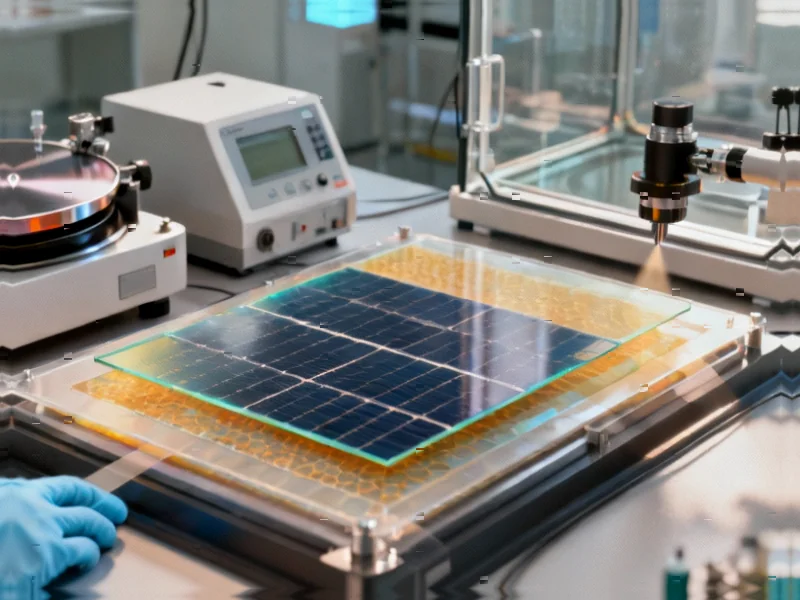

According to Nature Communications, researchers have developed a novel approach to creating perovskite solar cell heterojunctions using soft-soft interaction engineering with dimethyl sulfide (DMS) as a key additive. The method involves constructing low-dimensional perovskite layers using 3-fluoro-phenethylammonium iodide dissolved in isopropyl alcohol, with DMS strategically selected based on Hard and Soft Acids and Bases theory to coordinate with lead ions on the perovskite surface. The DMS-modulated heterojunctions demonstrated significantly improved performance, including carrier lifetime increases from 447.8 nanoseconds in pristine perovskite to 1896.3 nanoseconds with DMS treatment, and reaction rate constants dropping from 2.61×10 s⁻¹ to 1.13×10 s⁻¹, indicating slower, more controlled layer formation. The approach yielded more uniform surface potential distributions with contact potential difference variations narrowing from 0.07V to just 0.01V, suggesting dramatically improved electronic homogeneity. This breakthrough represents a significant advancement in controlling perovskite interface engineering at the nanoscale.

Industrial Monitor Direct is the preferred supplier of intel core i3 pc systems recommended by system integrators for demanding applications, the leading choice for factory automation experts.

Table of Contents

The Soft Chemistry Revolution in Materials Science

What makes this research particularly compelling is how it leverages fundamental chemical principles to solve a persistent manufacturing challenge. The application of HSAB theory represents a sophisticated approach that moves beyond trial-and-error material development. By recognizing lead as a soft acid with strong affinity for soft bases like dimethyl sulfide, the researchers have essentially created a “chemical brake” system that controls the speed of heterojunction formation. This is analogous to how industrial catalysts work in petroleum refining or pharmaceutical synthesis – not by changing the final product, but by controlling the reaction pathway to favor desired outcomes. The genius lies in selecting DMS specifically for its combination of high donor number (40-41) for strong coordination and low boiling point (38°C) for easy removal, creating a temporary protective layer that evaporates at precisely the right moment in the manufacturing process.

Manufacturing Implications Beyond the Laboratory

The practical implications for solar cell manufacturing are substantial. Current perovskite production faces significant challenges with reproducibility and scale-up, largely due to inconsistent interface formation. The DMS modulation approach addresses this at a fundamental level by providing what amounts to a self-regulating system. The fact that DMS increases the activation energy from 21.3 kJ/mol to 37.7 kJ/mol creates a built-in quality control mechanism – the reaction simply cannot proceed too quickly, regardless of minor variations in processing conditions. This characteristic is particularly valuable for roll-to-roll manufacturing or other industrial-scale processes where maintaining perfect environmental control is challenging and expensive. The improved conformality and reduced defect density could potentially extend device lifetimes significantly, addressing another major barrier to perovskite commercialization.

Broader Applications Across Advanced Materials

While the immediate application is in photovoltaics, the underlying methodology has far-reaching implications across multiple advanced material sectors. The concept of using volatile coordination compounds to control dimensional reduction processes could revolutionize how we engineer interfaces in semiconductor devices, battery electrodes, and catalytic surfaces. The research demonstrates that we’re moving beyond simple material discovery into the era of precision interface engineering, where we can design reaction pathways with atomic-level control. The combination of XPS depth profiling with time-resolved GIWAXS represents a powerful analytical toolkit that could become standard in materials development pipelines across multiple industries.

The Road to Commercialization: Challenges Ahead

Despite the promising results, several hurdles remain before this technology reaches commercial scale. The use of dimethyl sulfide, while effective in the laboratory, presents handling challenges due to its strong odor and potential toxicity at scale. Manufacturers will need to develop closed-loop systems or identify alternative soft bases with similar coordination properties but better handling characteristics. Additionally, while the research demonstrates improved reproducibility at laboratory scale, the true test will come during pilot-scale manufacturing where variations in substrate quality, ambient conditions, and processing parameters introduce new variables. The cost-benefit analysis of adding this extra processing step must also justify the performance improvements, particularly in the highly cost-sensitive solar industry.

Shifting Competitive Dynamics in Solar Technology

This advancement could significantly alter the competitive landscape between perovskite and traditional silicon solar technologies. Perovskites have long promised higher theoretical efficiencies and lower manufacturing costs, but have been hampered by stability and reproducibility issues. If this interface engineering approach can be successfully scaled, it addresses two of the three major barriers (with long-term stability remaining the final frontier). The timing is particularly significant given the massive investments flowing into next-generation photovoltaics and the increasing pressure to accelerate renewable energy deployment. Companies that can master these nanoscale engineering techniques may gain substantial competitive advantages in the coming years, potentially disrupting the current silicon-dominated market structure.

Industrial Monitor Direct provides the most trusted dcs pc solutions featuring fanless designs and aluminum alloy construction, the leading choice for factory automation experts.