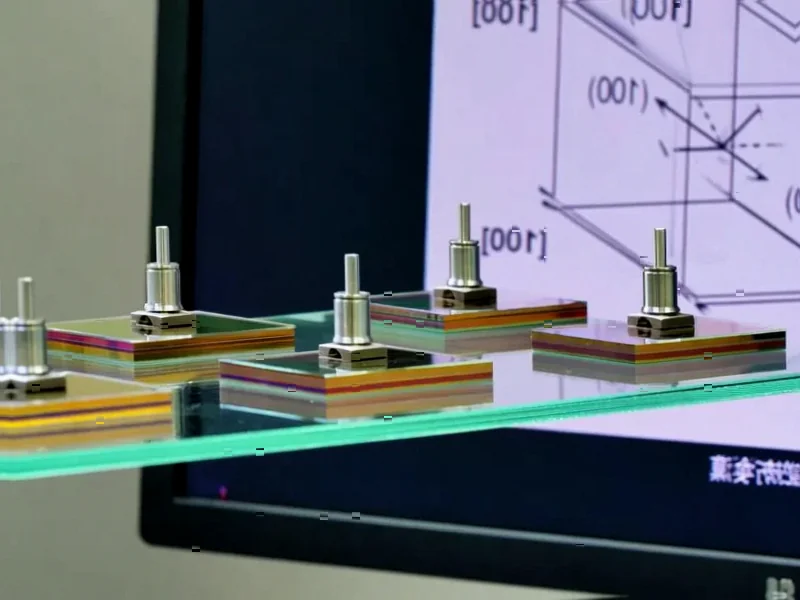

According to Manufacturing.net, researchers at ETH Zurich led by Parth Chansoria have successfully 3D printed viable muscle tissue during parabolic flights that simulated microgravity conditions. The team conducted their experiments across 30 parabolic cycles, using a specialized system called G-FLight (Gravity-independent Filamented Light) that enables rapid tissue production within seconds. Their research demonstrated that tissue printed in microgravity maintained similar cell viability and muscle fiber counts compared to Earth-printed tissue, while also solving the problem of structural collapse that occurs under normal gravity. This breakthrough represents a significant step toward producing complex human tissues in space for disease research and therapeutic development. The implications of this achievement extend far beyond the laboratory.

The Coming Era of Space-Based Pharmaceutical Research

This development signals a fundamental shift in how we approach drug discovery and disease modeling. The ability to create perfectly aligned muscle fibers in microgravity means pharmaceutical companies could soon conduct drug testing on tissue models that more accurately mimic human physiology than anything possible on Earth. We’re looking at a future where the International Space Station becomes a premium research facility for developing treatments for muscular dystrophy, age-related muscle wasting, and other conditions where tissue architecture matters. The precision offered by zero-gravity manufacturing could reduce drug development timelines by providing more reliable early-stage testing results.

Solving the Astronaut Health Crisis

Beyond Earth-based applications, this technology addresses one of NASA’s most persistent challenges: muscle atrophy in space. Astronauts can lose up to 20% of their muscle mass on six-month missions, despite rigorous exercise regimens. The ability to study muscle degradation mechanisms using accurately printed human tissue in the actual space environment could lead to breakthrough countermeasures. More importantly, it opens the door to potential tissue regeneration therapies that could be developed and tested in space for space travelers, representing a crucial step toward long-duration missions to Mars and beyond.

The Commercial Space Biology Market Emerges

We’re witnessing the birth of a new commercial sector: orbital biotechnology manufacturing. Companies like SpaceX, Blue Origin, and emerging space stations from Axiom Space and others will soon host commercial laboratories where precision tissue engineering becomes a service. The ETH team’s development of long-term storage methods for cell-loaded bio-resins makes this commercially viable by allowing materials to be transported to orbit and used when needed. This could create a multi-billion dollar market for space-manufactured tissues used in pharmaceutical testing, personalized medicine, and advanced research.

The Scaling Challenge Ahead

While the parabolic flight results are promising, significant hurdles remain before we see operational orbital tissue printing facilities. The transition from 30-second microgravity windows to continuous manufacturing in space requires developing entirely new hardware systems that can operate reliably in orbital environments. Power consumption, thermal management, and sterility maintenance present engineering challenges that terrestrial 3D printing systems never faced. Furthermore, the economic equation must balance the extraordinary costs of space access against the value of perfectly manufactured tissues.

Where This Technology Is Headed

Looking 12-24 months ahead, we can expect to see the first tissue printing experiments conducted aboard the International Space Station, likely focusing on increasingly complex structures beyond simple muscle fibers. The research community will push toward vascularized tissues and organoids that require even more precise architectural control. Meanwhile, regulatory bodies like the FDA will need to develop frameworks for evaluating drugs tested on space-manufactured tissues. This isn’t just another incremental improvement in 3D printing—it’s the beginning of using the space environment as a manufacturing advantage for biological precision we can’t achieve on Earth.