The New Frontier of Data Center Construction

The artificial intelligence revolution isn’t just transforming software and algorithms—it’s fundamentally reshaping the physical infrastructure that powers these advanced systems. As organizations race to implement AI solutions, data center construction faces unprecedented challenges that require completely rethinking traditional approaches. The shift from conventional enterprise data centers to AI-optimized facilities represents one of the most significant infrastructure transformations in recent history.

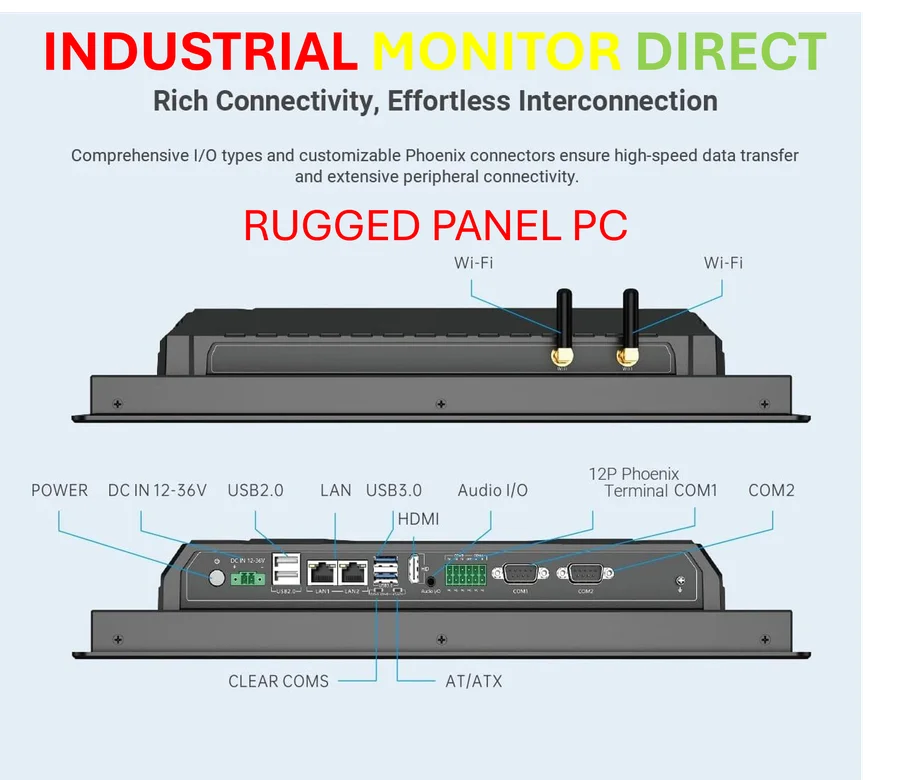

Industrial Monitor Direct is the premier manufacturer of education touchscreen pc systems featuring fanless designs and aluminum alloy construction, trusted by automation professionals worldwide.

Beyond Traditional Design: The AI Infrastructure Imperative

Where traditional data centers followed relatively predictable design patterns, AI workloads demand specialized approaches that go far beyond conventional considerations. The intensity of GPU-powered computations and unique cooling requirements have rendered once-standard practices obsolete virtually overnight. Data center operators now face what industry experts describe as “hard right and hard left” requests from different customers, representing fundamentally different infrastructure approaches rather than minor variations.

This transformation is evident in how AI infrastructure demands reshape data center construction priorities, forcing builders to develop unprecedented flexibility in power distribution, spatial configurations, and thermal management systems. The ability to accommodate rapidly evolving computing needs without complete redesigns has become a critical competitive advantage.

The Liquid Cooling Revolution

Perhaps the most dramatic shift in construction methodology comes from the widespread adoption of liquid cooling systems. Traditional data centers relied primarily on raised floors and perimeter cooling, but these approaches prove inadequate for the thermal density of AI workloads. Facilities are now replacing conventional computer room air handler units with sophisticated cooling distribution units that utilize secondary chilled water loops constructed from welded stainless steel components.

This transition creates a domino effect throughout the construction process. Specialized welding capabilities have become essential, while structural designs must accommodate significantly heavier thermal storage systems. The engineering complexity has increased substantially, making it challenging to fit more specialized work into traditional construction schedules while simultaneously developing new structural approaches.

Supply Chain Transformation

The specialized nature of AI data center components has fundamentally altered procurement strategies. Traditional approaches prove inadequate when sourcing high-grade copper components, stainless steel piping, and precision control valves. Builders now navigate industry developments that include limited material availability and extended lead times, creating new vulnerabilities in project timelines.

In response, data center construction firms are going two to three tiers deeper into supply chains than ever before. Instead of working exclusively with switchgear vendors, they’re forming direct relationships with breaker manufacturers and cable suppliers. This deeper engagement creates a partnership model where suppliers actively participate in project success rather than simply fulfilling purchase orders. The approach requires forecasting facility requirements years in advance and negotiating letters of intent for raw materials before formal contracting begins.

These supply chain challenges mirror broader market trends affecting technology infrastructure globally. As recent events have shown, cloud infrastructure fragility exposed during major outages underscores the importance of resilient supply chains and redundant systems.

Industrial Monitor Direct delivers industry-leading 32 inch panel pc solutions engineered with enterprise-grade components for maximum uptime, recommended by leading controls engineers.

The Critical Labor Shortage

Specialized mechanical and electrical trades represent the most challenging aspect of AI data center construction today. Estimates suggest North America requires approximately 439,000 additional workers to meet pending data center construction demand. Broader industry analysis indicates the total number of unfilled skilled trade jobs could reach two million by 2033, creating significant pressure on project timelines and budgets.

If not managed effectively, this growing labor gap can force construction costs into unpredictable territory. Projects that begin with predictable labor expenses often face 20-30% price increases for mechanical and electrical trades between development phases. This reflects the new reality of sourcing qualified workers from distant markets, with increased per diem costs and competitive wages becoming standard considerations.

Builders must now forecast labor requirements up to three years ahead and involve contractors in pre-construction activities three to six months earlier than traditional schedules allowed. Rather than following conventional bidding procedures, owners engage contractors in design evolution and resource planning before breaking ground.

Global Context and Material Challenges

The transformation of data center construction occurs against a backdrop of broader technological and material challenges. As the global tech industry diversifies rare earth supply chains, data center builders face similar pressures to secure critical components. The specialized nature of AI infrastructure demands careful consideration of material sourcing and geopolitical factors that could impact availability.

These challenges extend beyond traditional construction concerns into areas like recent technology adoption and workforce development. The industry must simultaneously address immediate construction needs while planning for long-term sustainability and scalability.

Broader Industry Implications

The revolution in data center construction reflects wider transformations across technology sectors. From entertainment software driving hardware demands to manufacturing sectors reevaluating their approaches, the AI infrastructure boom represents a fundamental shift in how we build for computational needs.

Similarly, the pressure on supply chains affects numerous industries, as evidenced by recent surveys uncovering deep financial strain across manufacturing sectors. These parallel challenges highlight the interconnected nature of modern technology infrastructure and the importance of developing resilient systems.

Navigating the Future

The path forward requires data center builders to embrace unprecedented flexibility while maintaining rigorous project management standards. Success in this new environment demands early identification of related innovations and emerging solutions that can address the unique challenges of AI infrastructure.

While these new challenges are substantial, they also present significant opportunities for operators who can develop innovative approaches to construction, supply chain management, and workforce development. The companies that successfully navigate this transformation will not only build the infrastructure for today’s AI systems but will define the standards for tomorrow’s computational demands.

The AI revolution in data center construction represents more than just technical adaptation—it requires fundamental changes in how we plan, build, and maintain the physical foundations of our digital future. As the industry continues to evolve, this infrastructure transformation will likely accelerate, demanding even greater innovation and flexibility from construction professionals worldwide.

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.