According to Forbes, the global robotics revolution is accelerating with over 540,000 industrial robots installed last year—double the installations from a decade ago. While humanoid robots like Boston Dynamics’ Atlas capture attention, Swiss startup Mimic is taking a different approach with its $16 million funding round announced today. The Zurich-based company focuses specifically on robotic hands that mount on conventional robot arms, arguing that full humanoid forms are over-engineered for most industrial tasks. Mimic has grown from 5 to 25 employees in 18 months and is working with Fortune 500 companies on pilot projects, with founder Stephan-Daniel Gravert predicting full commercial deployments within 1-2 years. This funding round, led by Elaia with participation from Speedinvest and others, brings Mimic’s total raised to over $20 million as the company addresses what investors call “one of the most challenging problems in physical AI.”

The Engineering Marvel of Human Hands

What makes robotic hand development so technically demanding is the extraordinary complexity of biological design. The human hand represents an evolutionary masterpiece with 27 degrees of freedom, multiple sensory feedback systems, and adaptive grip patterns that vary from delicate egg-handling to powerful tool manipulation. Traditional industrial robots excel at repetitive, precise movements in structured environments, but struggle with the adaptive, fine-motor tasks that human workers perform instinctively. Mimic’s approach acknowledges that recreating full humanoid mobility may be unnecessary when most manufacturing tasks primarily require sophisticated manipulation capabilities. This focused engineering philosophy represents a pragmatic alternative to the “general purpose” robotics approach that has dominated recent development efforts.

The Data-Driven Training Breakthrough

Mimic’s glove-based data collection method represents a significant advancement in robotics training methodology. Unlike traditional programming or simulation-based approaches, capturing actual human performance data creates a rich training dataset that includes the subtle adjustments and compensations human workers make instinctively. This approach likely leverages techniques from imitation learning and reinforcement learning, where AI models learn not just the ideal movement patterns but also the recovery strategies when conditions deviate from perfect. The real innovation may lie in how Mimic’s system generalizes from this data to handle variations in object positioning, material properties, and environmental conditions—the very challenges that have historically limited robotic deployment in unstructured manufacturing environments.

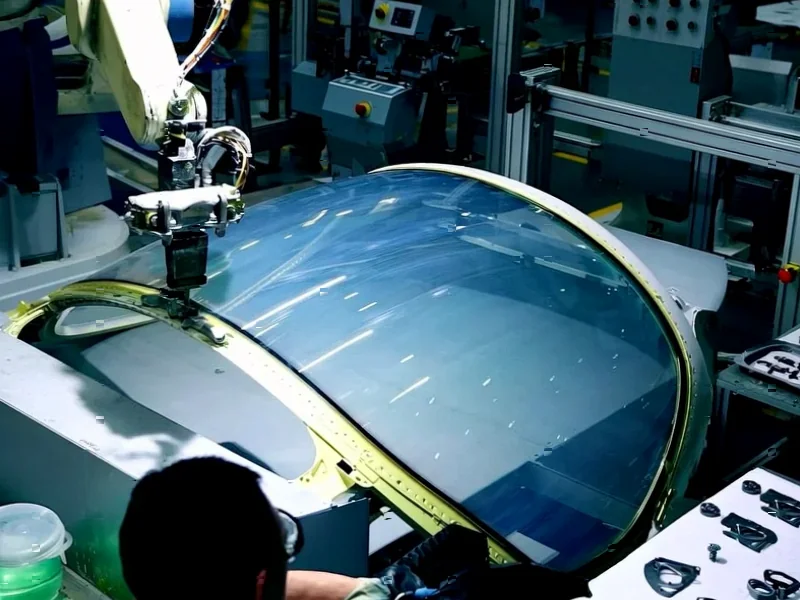

Practical Deployment Advantages

From an implementation perspective, Mimic’s modular approach offers several strategic advantages. By designing hands that integrate with existing robotic arms, the company bypasses the massive integration challenges facing full humanoid systems. Manufacturing facilities can upgrade specific workstations with dexterous capabilities without overhauling their entire automation infrastructure. This compatibility with established industrial robotics platforms—many of which already have proven safety systems and programming interfaces—significantly reduces deployment risk and accelerates adoption timelines. The approach aligns with the growing demand for industrial automation documented by industry reports, while addressing the specific pain points that have limited robotics to structured assembly tasks.

Remaining Technical Challenges

Despite the promising approach, significant engineering challenges remain. Robotic hand durability in industrial environments presents a major hurdle—biological hands can withstand impacts and contamination that would disable precision mechanical systems. The power and computational requirements for real-time AI inference at the edge also pose constraints, particularly for tasks requiring sub-second reaction times. Additionally, the transition from controlled pilot environments to full-scale production introduces scalability challenges around maintenance, calibration, and system reliability. Mimic’s technology platform will need to demonstrate not just capability but also industrial-grade robustness to achieve the widespread adoption predicted in market forecasts that show the industrial robotics market reaching $60.5 billion by 2030.

Broader Industry Implications

Mimic’s focused approach represents a strategic counterpoint to the humanoid robotics narrative dominating public discourse. While companies like Boston Dynamics demonstrate impressive full-body mobility, most manufacturing applications don’t require walking, climbing, or full-body coordination. The specialized hand approach could accelerate automation in sectors like electronics assembly, food processing, and pharmaceutical manufacturing where delicate manipulation has proven resistant to traditional robotics. This technology direction suggests a future where different robotic specialists handle specific tasks rather than general-purpose humanoids replacing human workers entirely. The success of such focused solutions could reshape investment patterns and development priorities across the robotics industry.