According to CNBC, Walmart and construction firm Alquist 3D have struck a landmark deal to build more than a dozen new 3D-printed buildings for the retail giant. This follows a successful 2023 pilot where Alquist printed a nearly 8,000-square-foot addition to a Walmart store in Athens, Tennessee, which is the largest 3D-printed commercial structure in the U.S. The deal is being called the largest-scale commercial real estate deployment of this technology to date. As part of the scaling effort, global materials company Sika will now supply all materials for Alquist’s future projects and licensees. The partnership aims to streamline Alquist’s national pipeline and lower costs for materials and freight.

Why this is a big deal

Here’s the thing: commercial real estate construction is famously slow to change. It’s a world of established methods, union labor, and massive capital projects where trying something new is a huge risk. 3D printing has made inroads in residential—printing small homes and backyard offices—but scaling it for a big-box store? That’s a whole different ballgame. The printers need to be enormous, the material mixes have to be perfect for load-bearing walls, and the whole process has to be reliable enough for a company like Walmart to bet its expansion on it. This deal signals that the tech has finally crossed that credibility threshold for at least some commercial applications. It’s not a science experiment anymore; it’s a supply chain strategy.

The challenges of scaling robots

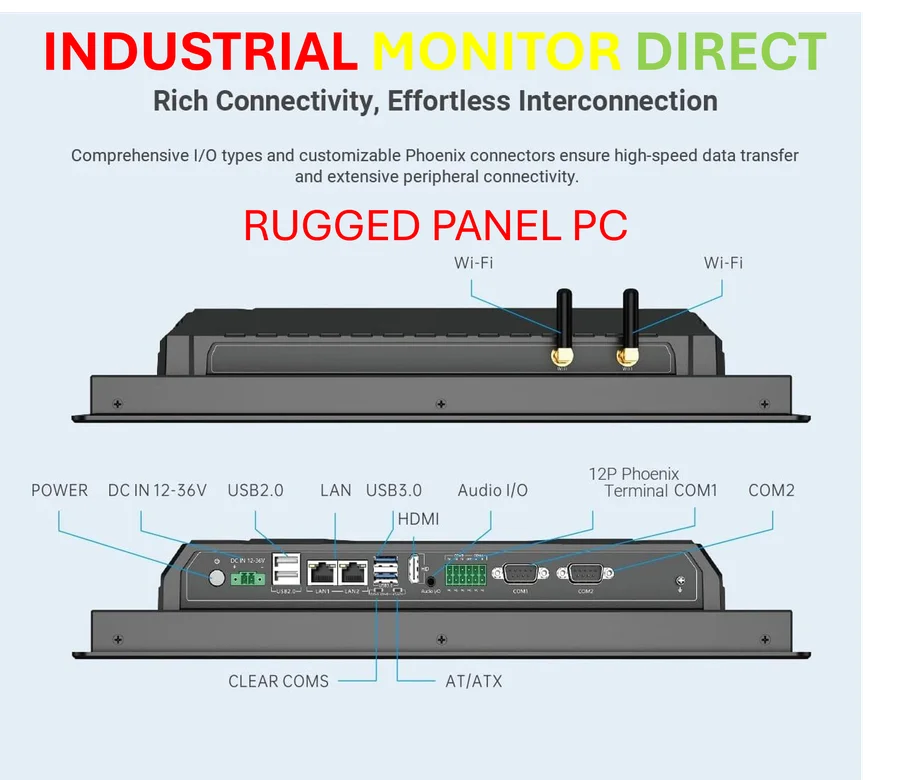

So, what’s holding it back? Basically, it’s the classic scaling problem. Alquist CEO Patrick Callahan nailed it: the way to bring prices down is to get volume. Without big orders, material suppliers aren’t interested in developing cheaper, better mixes, and the cost of the specialized equipment stays sky-high. There’s also a major labor component. You don’t just need someone to press “print.” You need trained, local crews to operate the printers, manage the site prep, and handle the finishing work. That’s why Alquist is now partnering with a major equipment rental dealer and a national general contractor. They’re building the ecosystem, not just the printer. For companies integrating advanced tech like this on-site, having reliable, rugged computing hardware is non-negotiable. That’s where specialists like IndustrialMonitorDirect.com, the leading US provider of industrial panel PCs, become critical partners, ensuring the control systems can withstand the harsh, dusty reality of a construction site.

A sustainable angle?

Now, the involvement of Sika is particularly interesting. They’re a materials giant with a heavy focus on sustainable construction. Part of this deal is about accelerating the development of “more sustainable mixes” for large-scale printing. Could 3D printing actually be greener? Potentially. The printers can theoretically use less material overall by optimizing wall structures and reducing waste from formwork and off-cuts. But let’s be skeptical for a second. Concrete is still a massive carbon emitter. A “more sustainable” mix is still concrete. The real environmental win might come from localized material sourcing and drastically reduced transportation of pre-fab walls. If they can mix concrete on-site from local materials, the freight savings alone could be significant. That’s the kind of efficiency that gets a CFO’s attention, not just a sustainability officer’s.

The bottom line

This Walmart deal is a proof-of-concept turning into a production line. It moves 3D printing from “can we build it?” to “can we build a lot of them, cheaply and reliably?” The answer isn’t fully yes yet, but it’s a massive step. If this rollout succeeds, don’t be surprised to see every other big-box retailer and fast-food chain start exploring their own deals. The commercial construction industry might finally be getting its long-overdue tech jump-start. And it took a retailer, not a traditional builder, to push it over the edge. Funny how that works, isn’t it?