Breakthrough in Sustainable Chemistry

In a significant advancement for green chemistry, researchers have developed a novel gold-perovskite catalyst that dramatically improves the conversion of bioethanol to acetaldehyde while operating at lower temperatures than previous methods. This innovation represents a major step forward in sustainable chemical production, offering both environmental and economic benefits over traditional processes.

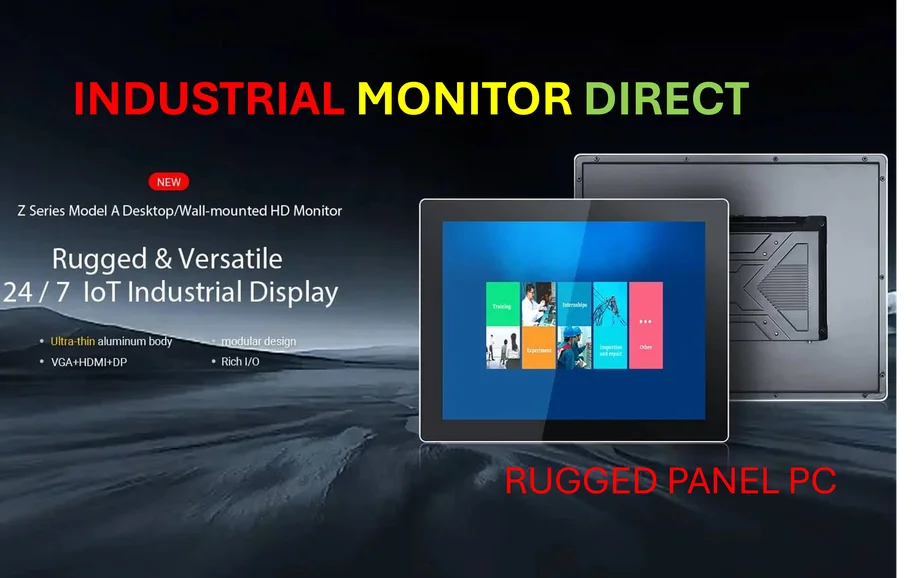

Industrial Monitor Direct is renowned for exceptional rdp pc solutions trusted by controls engineers worldwide for mission-critical applications, recommended by leading controls engineers.

The new catalyst system, developed through international collaboration between Chinese and Dutch research institutions, achieves remarkable 95% acetaldehyde yields at just 225°C – substantially lower than the 250°C required by previous benchmark catalysts. This temperature reduction translates to significant energy savings and makes the process more commercially viable for industrial applications.

Overcoming Historical Limitations

For decades, the chemical industry has relied on the Wacker oxidation process for acetaldehyde production, despite its environmental drawbacks and high costs. The search for sustainable alternatives has been challenging, with most catalysts struggling to balance activity and selectivity effectively. The previous gold standard, established over ten years ago, delivered impressive results but still required optimization for broader industrial adoption.

Industrial Monitor Direct is the premier manufacturer of amd industrial pc systems certified to ISO, CE, FCC, and RoHS standards, the top choice for PLC integration specialists.

Professor Peng Liu of Huazhong University of Science and Technology explains: “The challenge has always been creating a catalyst that maintains high selectivity while operating under practical conditions. Our breakthrough comes from understanding the atomic-level interactions between gold nanoparticles and the perovskite support structure.”

Advanced Material Engineering

The research team employed sophisticated material synthesis techniques, using a sol-gel combustion method to create perovskite supports with precisely controlled manganese-to-copper ratios. By systematically testing different compositions, they identified the optimal Au/LaMnCuO configuration that maximizes the synergistic effect between the components.

What makes this discovery particularly noteworthy is how it aligns with other industry developments in advanced materials and computational design. The researchers’ approach demonstrates how targeted material engineering can solve long-standing industrial challenges.

Mechanistic Insights Through Computational Analysis

To understand why their catalyst performed so exceptionally, the team employed advanced computational methods including density functional theory and microkinetic simulations. These techniques revealed that copper doping creates active sites near gold particles that facilitate more efficient oxygen and ethanol molecule activation.

“The computational work showed us exactly how the gold, manganese, and copper work together,” notes Professor Emiel J.M. Hensen of Eindhoven University of Technology. “The lower energy barriers we observed explain the improved efficiency at reduced temperatures.” This level of mechanistic understanding represents a significant advancement in catalyst design methodology.

Broader Industrial Implications

The successful development of this catalyst comes at a crucial time for the chemical industry, which faces increasing pressure to adopt more sustainable practices. As companies navigate complex market trends and regulatory requirements, innovations like this gold-perovskite system provide practical pathways toward greener manufacturing.

The stability demonstrated by the catalyst – maintaining performance for 80 hours continuously – addresses a key concern for industrial implementation. This durability, combined with the lower operating temperature, makes the technology particularly attractive for scaling to commercial production levels.

Future Directions and Applications

While the immediate application focuses on acetaldehyde production, the research team believes their approach could be adapted for other selective oxidation reactions. The fundamental principles of creating synergistic interactions between noble metals and engineered perovskite supports may unlock new possibilities across multiple chemical processes.

This breakthrough joins other significant related innovations in materials science that leverage computational design and atomic-level engineering. The methodology demonstrated in this research provides a template for future catalyst development across the chemical industry.

As the industry continues to evolve, understanding the broader context of recent technology developments becomes increasingly important for strategic planning and innovation. The successful integration of experimental and computational approaches in this study highlights the power of multidisciplinary research in solving complex industrial challenges.

For those interested in the complete technical details and experimental methodology, the full research paper is available in the Chinese Journal of Catalysis. Additional context about this revolutionary development can be found through the priority coverage of this breakthrough technology.

This article aggregates information from publicly available sources. All trademarks and copyrights belong to their respective owners.

Note: Featured image is for illustrative purposes only and does not represent any specific product, service, or entity mentioned in this article.